|

| X-Ray

Inspection - The Glenbrook Jewel Box Series |

|

| |

|

|

|

|

Jewel

Box 70-T

|

Jewel

Box 90-C

|

|

| |

Glenbrook’s

Jewel Box systems, designed for demanding applications, are used in

the world’s most discriminating laboratories and research facilities for

product development, failure analysis, non-destructive testing and research.

Glenbrook has incorporated ultra-high resolution, powerful microfocus

x-ray tubes, five-axis positioners and sophisticated software into systems

that are typically half the size and half the cost of other systems with

similar specifications.

The Jewel Box Series is divided into two broad categories, the Jewel Box

70-T and Jewel Box 90-C, each of which can be adapted or customized for

specific applications:

The Jewel Box 70-T delivers magnification up to 500X.

The Jewel Box 90-C provides ultra-high magnification up to 2000X. |

| |

|

| |

Both product

lines use the patented MXRA x-ray camera, which is unequaled in its ability

to image soft materials such as plastics, polymers, collagen and rubbers,

as well as other low-density materials, including ceramics and titanium.

High-Resolution Inspection for Electronics Fabrication Applications

When used with the GTI-5000 Image Processing Workstation, Jewel Box x-ray

inspection systems become powerful tools to evaluate electronic components,

including BGAs, Micro-BGAs and flip chips. |

| |

|

| |

| Glenbrook's

Jewel Box delivers superior

image quality - with excellent resolution and sensitivity - for laboratory

and failure analysis applications. The system's high-resolution X-ray

camera and 10-micron MicroTech X-ray source provide magnification from

15X up to 500X, with resolution of 100 line pairs/mm. |

| |

|

| |

| Progressive

magnification allows inspection of multiple details. |

| |

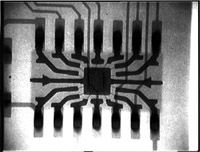

24X

view of an IC

24X

view of an IC |

The

same IC at 65X

The

same IC at 65X |

| |

|

| |

|

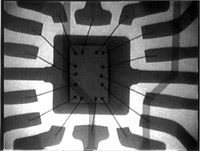

At

250X, ball bonds may be inspected

At

250X, ball bonds may be inspected |

Also

at 250X, wedge bonds are revealed

Also

at 250X, wedge bonds are revealed |

|

| |

| With

these advanced capabilities, the desktop Jewel Box produces images comparable

to those from X-ray inspection systems that are ten times larger in size,

and five times higher in cost. |

| |

|

| |

High-resolution

inspection applications:

sample images of defects as viewed on the Jewel Box |

| |

|

|

| |

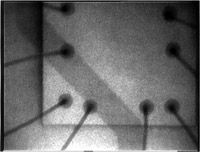

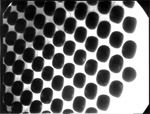

Dimensional

view of solder balls

Dimensional

view of solder balls

pinpoints the precise location

of solder voids within the balls. |

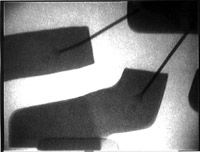

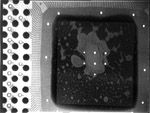

Die

attach, showing voids

Die

attach, showing voids

in the epoxy connecting the

silicon to the metal lead frame. |

|

| |

|

| |

In

addition to generating high-quality images of solder joints and bonds

in advanced technology packages that cannot be verified by visual inspection.,

the Jewel Box has the sensitivity to inspect soft materials, such as molded

plastics and encapsulants, as easily as components and electronic assemblies.

The transparent enclosure on all four sides of the Jewel Box allows easy

viewing from any angle. The positioner features five-axis control, including

360° rotation and tilt. The quadratic proportional controller ensures

precision control over the full range of posi-tioning speeds.

The Jewel Box employs Glenbrook's patented, award-winning X-ray camera

technology . The system has a compact footprint and may be placed on a

desk or countertop, or mounted on an optional wheeled cabinet base. |

| |

|

| |

|

|

| |

|

| |

|

|

| |

|

| |

| |