|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| X-Ray Inspection - PCB Fabrication | |||

|

|||

| The Pioneer continues to lead. | |||

| PCB

Inspection Systems Since the company's founding, Glenbrook's real-time X-ray inspection systems have enabled fabricators of multi-layer PCBs to enhance product quality and control costs. Inspection is performed following lamination, to determine the presence and degree of innerlayer shifts. At the onset of either conventional or small hole drilling, inspection is used to qualify hole-pad alignment. In addition to enhancing product quality, X-ray inspection enables users to control costs by eliminating defec-tive boards early in the production process. Among PCB fabricators, the RTX-113 is the most widely used Glenbrook system. For users of multi-wire, multi-layer technology, the RTX-Dual-VU allows confirmation of electrical continuity of the plating after drilling. For advanced PCB fabrication: Glenbrook's small hole drilling package. To resolve the challenge of verifying drilling registration for small holes, Glenbrook's small-hole drilling package allows users to inspect both standard and small holes with speed, accuracy and reliability. All the detail required to inspect this advanced technology, as well as standard holes, may be observed with a full one-inch diameter field of view. |

|||

|

|||

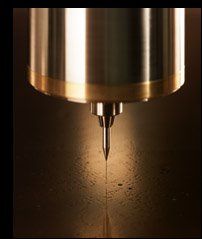

| The small

hole drilling package is available on new Glenbrook RTX Series

real-time X-ray inspection systems, and may be retrofitted to existing

units as well. Elements of the package include: The XRTV Zoom camera, providing 7X to 40X magnification over a one-inch field of view, enabling users to verify drilling registration on standard and small-diameter holes simultaneously. The RTVA B&W Image processor, is a self contained image processor which accepts a standard RS-170 (BNC) video input of a black and white real-time x-ray image and then performs frame averaging (for image clarity), two levels of contrast adjustment and video image freeze. GTI-3000 PCB Analysis: The GTI-3000 Computer Image Processor is designed for PC Board fabrication. The software permits X-Y offset measurements of drilled holes and pads as well as linear distances and hole diameters. Images can be stored and transmitted as jpg files. Additional features include: frame averaging (for image clarity), manual and automatic contrast adjustment. MicroTech™ 10-micron x-ray source (225x) |

|||