|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| X-Ray Inspection - Software & Options | ||||||||||||

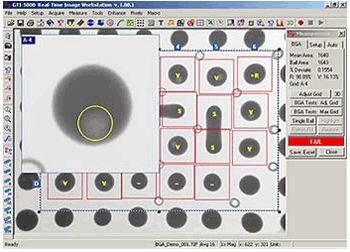

| GTI-5000

Software Glenbrook's GTI-5000 image processing software includes the advanced auto-BGA analysis software. These tools are incorporated into all new GTI-5000 software and are also available to all previous versions of the GTI-5000 as an upgrade. The GTI-5000 can automatically set up grids and quickly provide analysis for ball grids arrays, including percent void, roundness size, and bridging. |

||||||||||||

|

||||||||||||

|

GTI-5000

image processing software

|

||||||||||||

| The

GTI-5000 includes the following features: Sharpens live images continuously to increase resolution. Reduces noise by real-time frame averaging up to 256 frames. Produces ultra-high contrast. Reveals image details with filters, zoom and contour relief. Subtracts live images to detect small differences. Allows you to create and save user-specified image files. Annotates with labels, headers, arrows, and time/date stamps. Saves up to 10 preset calibrations. Reads image intensities of pixels, histograms, and line profiles. Easy-to-learn operations with on-screen help. Saves images to hard drive with a single click. Prints entire screen or image with color graphics. Saves measurement data directly to Excel spreadsheets. Sends e-mail with the displayed image attached. 3-D image rendering...and more. |

||||||||||||

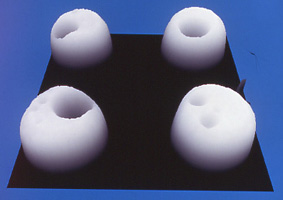

The 3-D Rendering Tool, using greyscale values as the third dimension, provides graphic images that can be rotated for quick visual interpretation. |

||||||||||||

| GTI-3000

PCB Analysis

The GTI-3000 Computer Image Processor is designed for PC Board fabrication. The software permits X-Y offset measurements of drilled holes and pads as well as linear distances and hole diameters. Images can be stored and transmitted as jpg files. Additional features include: frame averaging (for image clarity), manual and automatic contrast adjustment. The GTI-3000 package includes CPU, Frame Grabber, Software and Color Monitor. |

||||||||||||

| GTI-1000

Versatile Application

The GTI-1000 is a versatile Computer Image Processor for providing image clarity through frame averaging, image save, linear measurement and contrast adjustment. The GTI-1000 package includes CPU, Frame Grabber, Software and Color Monitor. |

||||||||||||

| RTVA

Basic B&W Image Processor The RTVA is a self contained image processor which accepts a standard RS-170 (BNC) video input of a black and white real-time x-ray image and then performs frame averaging (for image clarity), two levels of contrast adjustment and video image freeze. |

||||||||||||

| RTQ.5

image processor with advanced electronic zoom and panning, on-screen text labeling, time and date display, plus pseudo color and 3-D-appearing images. Five styles of distance measurement include solder ball pitch spacing and "center to center" for measuring hole-to-pad offsets. Effective gain, contrast and image-sharpening enhancements allow inspection of dense electronic packages. A 32-image memory allows up to 32 different areas of an assembly to be captured and compared. |

||||||||||||

| Further

Options to enhance the capabilities of your Glenbrook real-time X-ray inspection system: |

||||||||||||

| Variable

Angle Viewing (VAV) Enables users to inspect solder joints on the underside of BGA components for process defects such as non-wetting and non-contact. VAV allows the X-ray source to be rotated on its axis, as needed, for oblique viewing. The variable angle viewing involves rotating the x-ray tube by 45°. This is controlled by the operator using a switch and driven by a motor. It is fully variable up to 45 degrees. This is available on the RTX-113, Dual VU and RTX-2500. By rotating the X-ray source, rather than the assembly being inspected, variable angle viewing may be achieved within existing RTX enclosures, rather than requiring an over-sized inspection cabinet. |

||||||||||||

|

||||||||||||

| Video

printer provides thermal prints of screen images for full documentation. |

||||||||||||

| XRTV

Zoom camera for variable 7X to 40X magnification over a one-inch field of view with high resolution, for small-hole drilling and BGA/flip chip applications. |

||||||||||||

| MicroTech

10-micron X-ray source with variable magnification up to 500X for multi-layers and assemblies with BGAs, µBGAs and flip chips, ICs and other components. |

||||||||||||

| Manual

X-Y positioning system Easy to use positioner for use with the RTX Series of x-ray inspection systems, mounts easily on the frame of the RTX and can be adjusted to handle any size part. (Used mainly for bare board inspection.) |

||||||||||||

| Motorised

X-Y positioner Allows 6" x 11" movement for the RTX-113 and The Dual-VU systems. This is a precision two speed positioner. The positioner can easily be retrofit on-site by a Glenbrook technician. |

||||||||||||

| Enlarged

frame for easy inspection of backplanes and other large, heavy substrates. |

||||||||||||