|

|

|

|

|

|

|

|

|

|

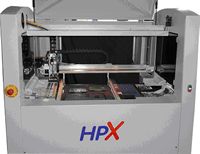

| SMD Assembly - HEEB-INOTEC Inoplacer HPX | ||

|

||

|

||

|

||

|

SMD

Assembly System for flexible SMD Assembly

Easy Programing and Operation High-Quality ICOS Vision system and BGA lighting Flexible Feeder system Intelligent CAN-BUS Feeder Sensor controlled Z-Axis Software module production programing Software module for Statistics |

||

| The "

INOPLACER HPX " automatic SMD assembly system is based on the continuing

development and experience with the INOPLACER SM and INOPLACER AC automatic

SMD assembly systems. The "INOPLACER HPX" Automatic SMD Assembly System is specially developed for assembly of small and medium size batches. The machine is very easy to program and operate, with compact design and relatively inexpensive. The combination of laser centering from Cybertronics and vision system makes it possible to assemble a large range of components. The INOPLACER can be purchased in basic form, equipped with laser centering from Cybertronics as standard, to place components from 0402s to BGAs, but can also be easily up-graded with Heeb's unique vision system. This add-on will inspect the underside of all components prior to placement, and if for example there is a ball missing from a BGA or a lead missing form a leaded component the Inoplacer HPX will alert the operator to the problem. The vision system also handles 0201 components. |

||

| Centering:

Lasercentering, Cyberoptics Vision, ICOS X/Y motors: Bautz Motion control: PCI-Controller (assembled in the PC) Linear guides: THK Machine control: Industrial PC (Pentium) Movement belts: standard belts Power supply: Puls |

||

| Component

centering from small components is achieved with a LASER unit which is

integrated in the assembly head. Larger components are centered with the

vision system. Through the concept of an "open machine", it is very easy

to set up the machine and change from one job to the other. Also the pcb

handling is very easy and each machine could be integrated in a production

line with automatic pcb loading and unloading system (option), at a later

date. The machine can assemble a wide range of components from 0201 up to a size of 50 x 50 mm, ( PLCC’s, QFP’s, BGA’s ). It is possible to rotate, shrink and stretch assembly programs. The HEEB - INOTEC "INOPLACER HP " can use programs from the INOPLACER SM, INOPLACER AC, HM 60 and HM 230. The machine comes ready for production incl. control unit, camera, 4 assembly tools, pcb support, and 1 feederbank for max. 40 x 8 mm component lines ( 4 x Feederbox with 10 x 8 mm component lines, or 24 x 8 mm single feeder). |

||

| INOPLACER

HPX without Visionsystem. Assembly area: 400 x 500 mm (without right Feederbank) additional 280 x 400 mm (with right Feederbank) additional 155 x 400 mm (with In line System) 300 x 350 mm Smallest component: 0402 Largest component : 33 x 33 mm Placement rate max.: 4000 C/h. Placement rate average: 2500-4000 C/h. Assembly Accuracy: typ.+/- 0,09 mm Resolution X/Y - Axis: 0,013 mm Resolution Z - Axis: 0,04 mm Resolution D-Axis: 0,025° Max. 8 mm component lines: 154 Programing: Teach In & CAD Power: 230 V/50 Hz Air Supply: 6 bar, dry, oilfree, 50 NL/min Dimensions HxLxW in mm: 1530x2100x1400 Required Work Area: 4000 x 3000 mm Facility Requirements (humidity): 18-25°C, 48-60 % Weight: ca. 490 kg Colour: grey RAL 7035 |

||

| INOPLACER

HPX with Visionsystem. Assembly area: 400 x 500 mm (without right Feederbank) additional 280 x 400 mm (with right Feederbank) additional 155 x 400 mm (with In line System) 300 x 350 mm Smallest component: 0201 Largest component: 50 x 50 mm Placement rate max.: 4000 C/h. Placement rate average: 2500-4000 C/h. Assembly Accuracy Chip typ.+/- 0,09 mm QFP typ. +/-0,05 mm Resolution X/Y - Axis: 0,005 mm Resolution Z - Axis: 0,04 mm Resolution D-Axis: 0,025° Max. 8 mm component lines 154 Programing: Teach In & CAD Power: 230 V/50 Hz Air Supply: 6 bar, dry, oilfree, 50 NL/min Dimensions HxLxW in mm: 1530x2100x1400 Required Work Area: 4000 x 3000 mm Facility Requirements (humidity): 18-25°C, 48-60 % Weight: ca. 490 kg Colour: grey RAL 7035 |

||

| The machine

design is based on easily obtainable standard components and belts. The 'open' machine style allows easy set-up and PCB handling. Machines can also be integrated into a production line with automatic PCB loading & unloading. |

||